AL BAIANAT

Introduction

Albaianat specializes in AI-powered Digital Twin solutions for manufacturing and industrial operations.

In today’s fast-paced manufacturing landscape, unplanned downtime,

inefficient workflows, and rising energy costs are major challenges.

Digital Twin technology offers a breakthrough real-time simulation and

predictive insights that transform how factories operate.

We will introduce a cutting-edge Digital Twin platform designed to

optimize production, reduce failure risk, and enable data-driven

decision-making in complex industrial environments.

We create real-time simulations of production lines to optimize workflows, predict equipment failures, and reduce downtime.

Our platform combines IoT sensor integration, machine learning, and simulation analytics.

Key focus areas include predictive maintenance, control flow optimization, and energy efficiency.

We offer a modular Digital Twin Suite with what-if simulations, resource optimization, and anomaly detection.

Our infrastructure includes edge AI devices, cloud-native simulations, and real-time dashboards.

We help manufacturers cut operational costs, increase productivity, and meet sustainability goals.

Proven in automotive, FMCG, and logistics sectors through R&D pilots and industry partnerships.

About us

We are a forward-thinking startup focused on transforming

industrial operations through advanced simulation technologies.

Our team brings together experts in AI, IoT, and industrial

engineering to build intelligent platforms that model, predict, and

enhance real-world performance.

We are driven by a commitment to innovation, efficiency, and

solving complex operational challenges for manufacturers

worldwide.

Company Overview

At the core of our solution is a Digital Twin platform that creates

virtual replicas of manufacturing systems to enable predictive

maintenance, real-time analytics, and dynamic control flow

optimization.

By combining machine learning with edge computing and sensor

data, we help industrial clients reduce downtime, cut waste, and

optimize energy and resource usage delivering measurable impact

across high-volume production sectors.

Problems

Manufacturers across industries face growing challenges related to unplanned equipment downtime, inefficient workflows, and excessive energy and material waste.

Traditional production systems lack real time adaptability, leading to costly delays, maintenance overruns, and suboptimal resource allocation.

The absence of predictive insights and dynamic process control directly affects profitability, especially in high volume environments like automotive, FMCG, and heavy manufacturing.

Our Solutions

We offer an AI-powered Digital Twin platform that creates dynamic virtual replicas of industrial systems to simulate, monitor, and optimize operations in real time.

By integrating machine data, sensor networks, and advanced AI models, our platform enables predictive maintenance, dynamic workflow adjustments, and efficient energy usage.

This allows manufacturers to anticipate failures, reduce downtime, and maximize throughput—transforming operations from reactive to proactive.

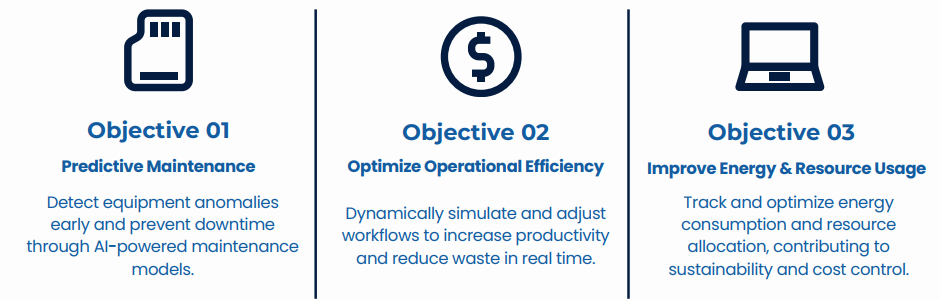

Our Objectives

Our objective is to revolutionize manufacturing performance through an intelligent Digital Twin platform that delivers predictive insights, real-time optimization, and enhanced resource efficiency.

We aim to empower industries with tools that enable smart, data-driven decision-making.

Contact us

4 Type of Digital Twins

Process Digital Twins

Process twins, the superior digital twin types, combine system twins into a single entity to investigate system synchronization and cooperation. This system provides the most comprehensive picture of how things happen inside the factory or plant.

System Digital Twins

System twins are copies of assets that show how multiple components come together to form functioning components at the system level. System twins offer a detailed perspective of the entire plant or manufacturing facility.

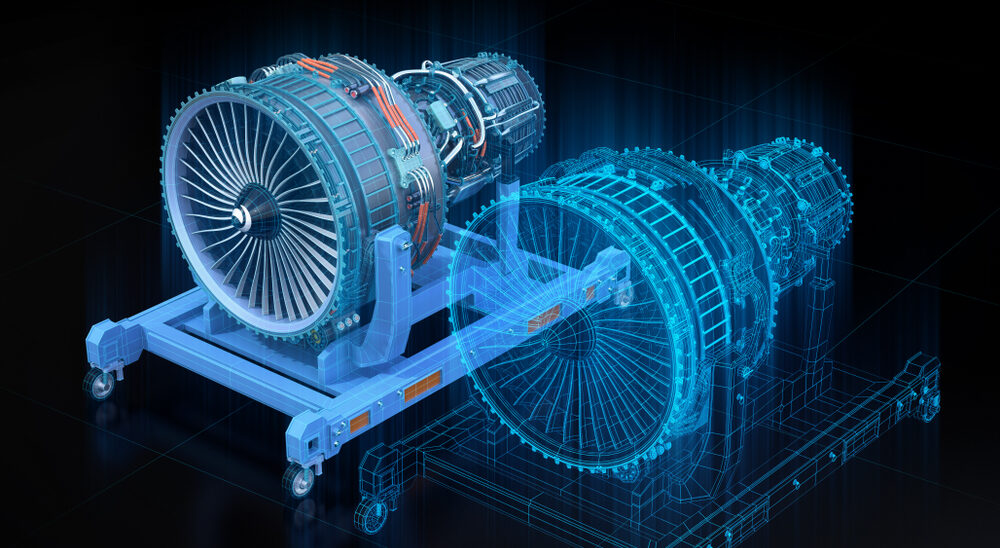

Product Digital Twin

A product or asset digital twin is a digital replica of tangible assets such as machinery, buildings, and automobiles. It offers updated information on an asset's atmosphere, performance metrics, and functional health.

Component Digital Twin

The most basic type of digital twin technology is known as the component twin or parts twin. It is equivalent to the simplest components of the system, such as a particular piece of machinery or a product, like a sensor, switch, valve, etc.

Some key Applications of Digital Twins

Predictive maintenance – Avoid equipment failures by simulating wear and tear.

Smart cities – Model traffic, utilities, and infrastructure for better planning.

Personalized healthcare – Create patient-specific models to test treatments.

Vehicle design – Simulate cars or aircraft before building prototypes.

Energy grid management – Monitor and optimize electricity flow in real time.

Retail logistics – Improve inventory and supply chain with virtual simulations.

Copyright 2025 © Albaianat company. All Rights Reserved.